JACK LEUNG

FOUNDER

Founder and CEO of AlS Home Group

2005 Graduated from Guangzhou Traffic Technician College

From 2005 to 2013, he worked for Toyota, Lexus, Land Rover, and other Fortune 500 automobile brands.

In 2014, he started his enterprising career in the real estate agency and catering industry and finally joined the wholehouse custom home furnishing, curtain wall, and window industry

Co-founded AIS Cabinetry, LONGTIME Furniture, HANLUN Facade, and AIS Furniture,

In 2022, he promoted the company to AIS GROUP

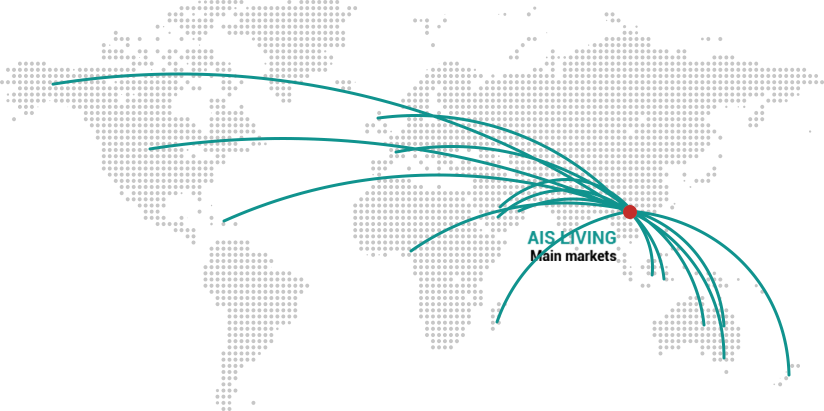

In 2023, he set up overseas branches to accelerate international business development.